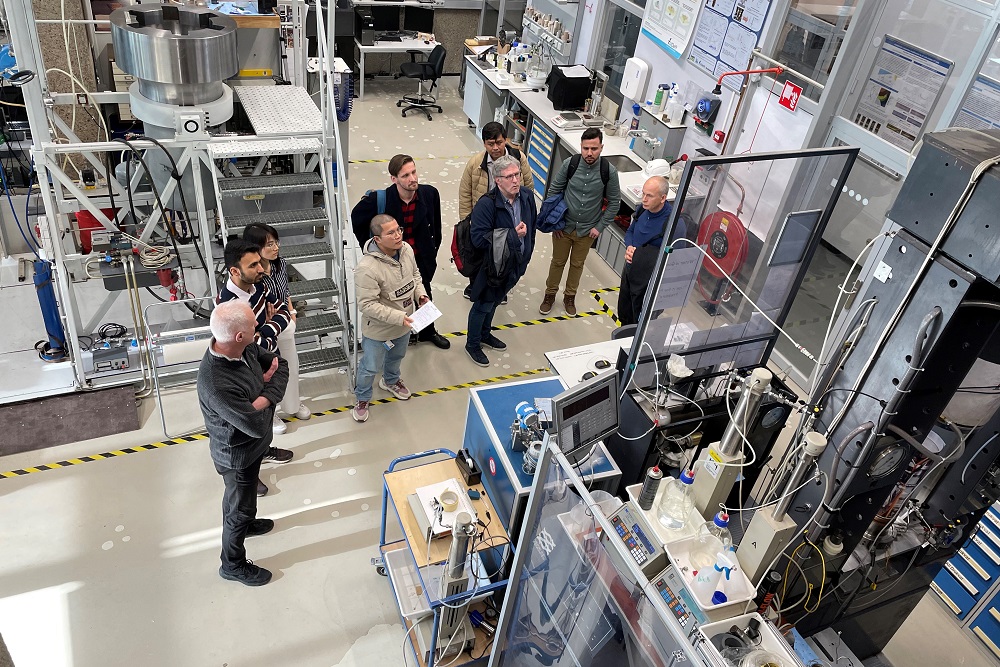

The SHARP project team members visiting the Northern Lights facility at Øygarden (in the background) in May 2024. Photo: SHARP project / ACT-CCS

Carbon Capture and Storage (CCS) is gaining momentum worldwide, with Norwegian CCS projects leading the way toward commercialization. CO2 capture from the cement plant at Brevik is set to start in 2025, and Northern Lights is ready to receive this CO2 at Øygarden outside Bergen and store it in a saline aquifer located 2.6 km below the seabed.

In the meantime, several future storage projects, often with higher capacity, are already progressing through the development pipeline. While CO2 storage is a proven technology in various geological settings (with Norway having injected CO2 into a subsurface reservoir at Sleipner since 1996), specific research challenges remain.

From 2020 to 2024, three research programs, funded by the “Accelerating CCS Technologies – ACT” program – were conducted with the participation of 16 countries, regions, and provinces looking to support research that leads to safe and cost-effective CCS technology. These projects include SHARP, CEMENTEGRITY, and RETURN.

Norway is not the only country incorporating CO2 storage as a key element in its energy transition plans; it is also a critical strategy for countries such as the Netherlands, the United Kingdom, and Denmark, i.e. those surrounding the North Sea.

Hence, the quest for safe and reliable CO2 storage sites in the North Sea is expected to accelerate, which means reliable and rapid evaluation of new large-scale subsurface storage solutions at the gigatonne-per-year level is essential.

SHARP: Geomechanical insights to reduce uncertainty

One of the uncertainties in evaluating proposed storage sites is how the local geomechanical environment will respond to CO2 injection. The SHARP project seeks to diminish this uncertainty to enhance the accuracy of managing the risks associated with subsurface CO2 storage containment. This improvement aims to reach a level of confidence that satisfies both commercial and regulatory interests.

First, the rheology and constitutive behavior of rock material from North Sea caprock and reservoir rock have been characterized in the laboratory, maturing the geomechanical readiness level for North Sea sites. Specifically, testing of more than 30 plugs from the Rotliegendes reservoir rocks from the location targeted by the Dutch ARAMIS project has shown the dependency of the rheological parameters on other measurable parameters such as porosity or acoustic velocities.

The rheological parameters are now implemented within SHARP into constitutive behavior models for hydromechanical modeling of reservoirs during CO2 injection.

Second, the subsurface stress models have been improved using borehole breakout data and a new earthquake catalog merging data from all countries around the North Sea. The new data is used to understand the possible reservoir deformation during CO2 injection. The experimental work is used to identify geophysical attributes relevant to monitoring of deformation.

By the use of geophysical proxies, the lab experiments have determined how we can employ geophysical monitoring techniques to detect changes in the reservoir during CO2 injection. Changes in acoustic wave velocity and amplitude accompany changes in reservoir conditions.

When applied together, it becomes feasible to make use of emerging fiber optic technologies to improve CO2 subsurface risk monitoring and management strategies worldwide.

CEMENTEGRITY: Ensuring wellbore integrity

The wellbores themselves are a critical potential leakage pathway for any subsurface reservoir. If such a wellbore leaks, it would form a direct route from the reservoir to the surface.

The ACT project “CEMENTEGRITY” focused on the development of wellbore sealants with improved resistance to exposure to CO2-based fluids. There are three critical abilities for any sealant material to be used in CCS: it needs to form a good seal in the well-caprock system (and maintain this through mechanical changes); it needs to chemically resist exposure to CO2-bearing fluids; and it needs to withstand thermal shocks or cycling without major damage.

Traditionally, wellbore sealants used in oil and gas wells are often based on Ordinary Portland Cement (OPC). For CO2 storage in depleted hydrocarbon reservoirs, OPC can be expected to be present in legacy wells.

When exposing OPC to CO2, chemical reactions between the CO2 and calcium in the OPC will initially lead to carbonation. However, during prolonged CO2 exposure, subsequent carbonate dissolution may lead to a loss of sealant integrity, and thus, potentially, leakage. Moreover, OPC fractures relatively easily when strained, for example, due to pressure or temperature changes.

To address this, CEMENTEGRITY has established key properties of wellbore sealants that can help ensure long-term seal integrity during CCS and identified testing methods for these properties.

By testing five different sealants, covering a range of compositions, CEMENTEGRITY has identified the critical sealant properties controlling its ability to form and maintain a seal with long-term integrity, that withstands the deleterious impacts expected during CO2 injection and storage, as well as the best testing methods for these properties.

Combined with a review of current regulations and industry recommendations, the identified key sealant properties are its permeability, mechanical properties (compressive and tensile strength, Young’s modulus, and Poisson’s ratio); and thermal properties (conductivity, heat capacity, expansion coefficient).

Furthermore, when testing candidate materials, in addition to measuring the impacts of exposure to CO2 on these key properties, changes in microstructure (porosity) and composition (both chemical and mineralogical) that may indicate degradation of the sealant should also be studied.

RETURN: Enabling cold and cost-effective CO2 injection

For the North Sea setting CO2 will be transported via pipelines. Therefore, the liquid gas is expected to be approximately 5 ˚C on arrival at the injection platform to be pumped into depleted gas fields. At this reservoir depth of 3 to 4 km depth, temperatures are around 100-120 ˚C.

The RETURN project investigated specifically whether cold CO2 injection into depleted fields is feasible and what recommendations can be made to enable it. Cold injection has a huge economic and technical advantage since the CO2 can be injected as is, i.e. it doesn’t need to be heated before injection into its storage reservoir. It can then be injected in liquid or supercritical form, which is denser, and thus it allows the operator to more rapidly inject large amounts of CO2.

RETURN investigated potential mechanical effects on rock strength due to the temperature contrast, in particular on the sealing caprock and well cement integrity. It can also lead to the formation of CO2 hydrates in the near-well area, reducing injection pathways through the porous rock and thus reducing injectivity and efficiency.

To model the large expected temperature contrasts, new software tools were also developed, enabling to couple well flow to reservoir flow simulations. No thermo-mechanical damage was documented in sandstone or cement specimens, although the reduction in injectivity was noticed and pressure cycling led to increased flow paths between cement and steel casing.

Modeling based on the laboratory findings suggests that only a negligible amount of CO2 would migrate out of its intended storage reservoir. The findings from the project are that for reservoirs presenting the same rock formations as those tested in the laboratory, there is room for cost-effective, cold injection.

Applicable to other storage technologies

While these projects focus on CCS settings, other geological storage technologies, such as hydrogen storage, will require similar technical investigations tailored to the specific chemical and physical environments of each application.

Thus, concepts and methodologies developed in these projects can readily be applied to the testing of other materials and chemical agents for other geological storage systems.

The collaborative funding mechanism of ACT has now been succeeded by the Clean Energy Transition Partnership (CETP).

For more information, see:

SHARP: SHARP-Storage – SHARP-Storage

RETURN: RETURN – Re-use of depleted oil and gas fields for CO2 sequestration

CEMENTEGRITY: Home | ACT CEMENTEGRITY

ANNE PLUYMAKERS, REINIER VAN NOORT, ELIN SKURTVEIT, AUKE BARNHOORN AND PIERRE CERASI