The green shift will significantly increase the demand for metals and minerals. Especially for cobalt, it may be necessary to look to the oceans for future production.

– It is impossible to cover future demand for a number of important minerals and metals from land-based deposits. That is why we need deep-sea minerals, said Tore Halvorsen, board member of the recent exploration company Loke Marine Minerals.

Halvorsen gave a lecture during the seminar Marine Minerals which was organized by GCE Ocean Technology and the Norwegian Forum for Marine Minerals (NMM) earlier this year.

There are three factors in particular that will contribute to the growth in demand – population growth, economic growth and the green shift. The first two have contributed to a relatively stable increase in demand for several decades.

The latter – the use of metals for technology development and the supply of green value chains – comes in addition.

Will significantly increase demand

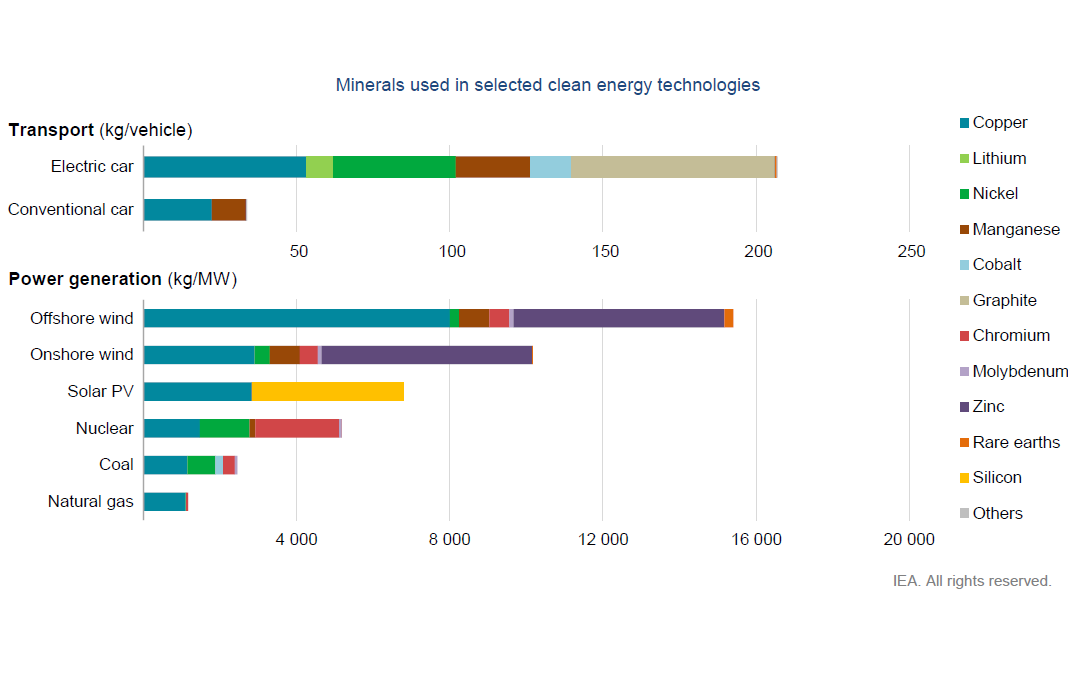

In May, the International Energy Agency (IEA) published a new report (The Role of Critical Minerals in Clean Energy Transition) concluding that the rapid development of the green shift will significantly increase the demand for some specific metals and minerals, mainly copper, lithium, nickel, cobalt and rare earth metals.

We also know that the levels in mines on land are declining almost year by year, and more and more countries and companies have therefore begun to focus on the deep sea.

Green technology demands much more metals and minerals than fossil based technology. Illustration: IEA

Green technology demands much more metals and minerals than fossil based technology. Illustration: IEA

This applies not least in Norway, where the government has been a strong driving force for mapping the Norwegian continental shelf (via the Norwegian Petroleum Directorate) and by starting an impact assessment program for mineral activities that can facilitate an opening process.

Related stories on geo365.no:

Dyphavsmineraler: Starter arbeidet med KU

«Norge må bli et foregangsland»

Cobalt in particular

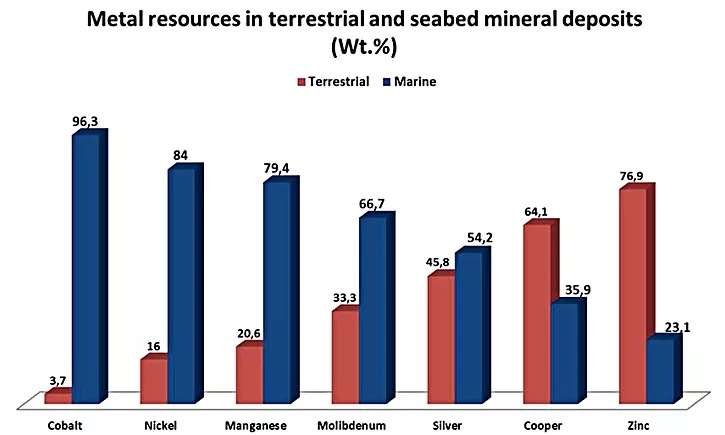

Halvorsen began the presentation showing a diagram from the USGS showing estimated metal resources on land and in the deep sea. The battery metal cobalt is in a special position with 3.7 per cent of estimated resources located on land, compared with 96.3 per cent in the ocean.

IEA writes in its report that the demand for cobalt can increase 6-30 times from the current demand, depending on technological development for batteries and the climate policy on which it is based. In the IEA Sustainable Development Scenario (SDS), the demand for the metal will be multiplied by 21 from 2020 to 2040.

Most of our cobalt resources are found in the ocean. Illustration: USGS

Most of our cobalt resources are found in the ocean. Illustration: USGS

IEA further points out that while the market for cobalt is in surplus in the short term, future production based on existing projects will not be able to cover future needs.

Today’s cobalt production also runs a political risk given that about 70 percent is extracted from only one country – Congo. China accounts for almost 70 percent of the global processing capasity of cobalt ore.

Can cover 10 percent

– Recycling is mentioned by the IEA as an important measure to ensure future supply of important metals and minerals. We embrace recycling, but it is not a complete solution.

For cobalt, the energy agency has estimated that recycling can cover 10 percent of demand.

– It is therefore difficult to see that deep-sea minerals will not play an important role in the green shift, Tore Halvorsen concluded.

|

Circular economy – but not today

During the digital seminar, many participants discussed the topics from the lectures and presented ideas, solutions and facts. In connection with a discussion about recycling, more specifically recycling of metals from electric vehicles (EV), former president of The Cobolt Institute David Weight wrote the following:

EVs are relatively new and the batteries have a life of about 10 years in this application. From then the batteries can be repurposed for use in stationary applications which enable renewable energy sources where they can operate satisfactorily for probably another 10 years or more.

Hence batteries ready for recycling are nowhere near a critical mass to instigate large scale operations and will not be so for some years. Also, there is no established recycling process available, though a number of processes are in operation. Vehicles at end of life are scrapped, then stripped down and recoverable materials recycled.

Currently the circular economy will not be workable for EVs because the sector is in a nascent phase with EVs replacing ICE vehicles and this is expected to accelerate – a large input of critical energy metals will be required until the sector is mature.

At that point the circular economic model can kick in and metals are perfectly suited for this as they are only ever used but not consumed in products and processes and so in theory are infinitely recyclable. |

The Norwegian Petroleum Directorate has stated that sulphide deposits have been found on the Norwegian shelf along the Norwegian part of the Mid-Atlantic Spreading Ridge (MASR). They are formed by present and past volcanic activity related to the seabed dispersal. Deposits available for extraction can be found within a belt along the spreading ridge where they have not had time to be buried too deeply by sediments.

Loke to present in Bergen

During the conference NCS Exploration – Deep Sea Minerals on October 20 and 21, the CEO of Loke Marine Minerals Walter Sognnes will give the presentation Sustainability through Technology.

In his presentation, Sognnes will explain how the company will benefit from decades of the framework and track-record from the oil and gas industry to implement hte most ambitious environmental plan in the mining industry.

Sognness will also state that Loke Marine Minerals will be a fast mover internationally, currently focusing on securing licences within the International Seabed Authorities jurisdiction. They also plan to apply for Norwegian acreage in 2023, should the opening process be finalized by then.

Loke’s main focus is mangenese crusts for which they have developed their own mining tool to extract.